- Silvassa - 396230, Dadra and Nagar Haveli , India

- info@gclglobalplastics.com

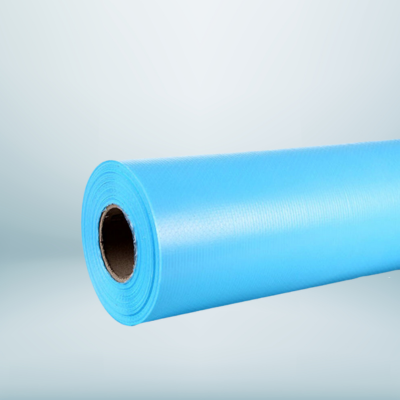

Perforated release film, also known as perforated release ply or breather ply, is a specialized material used in composite manufacturing processes, particularly in vacuum bagging applications. It serves multiple purposes in ensuring proper air evacuation, resin infusion, and achieving high-quality surface finishes on composite parts.

Perforated release films are designed with tiny perforations that allow air and excess resin to escape from the vacuum bagging setup during the curing process. These perforations facilitate the removal of trapped air and ensure uniform pressure distribution across the composite layup, which is critical for achieving optimal consolidation and eliminating voids.

In processes involving resin infusion, perforated release films enable controlled resin flow through the composite materials. The perforations help distribute resin evenly across the part, ensuring thorough impregnation of fibers and achieving consistent resin content throughout the laminate.

Perforated release films are widely used in aerospace manufacturing for producing composite components such as aircraft panels, fairings, and structural parts. They contribute to achieving lightweight and high-strength materials with superior mechanical properties and aerospace-grade quality.

In the wind energy industry, perforated release films play a crucial role in manufacturing composite blades for wind turbines. They enable efficient resin infusion and air evacuation processes, ensuring the production of durable and efficient turbine blades capable of withstanding harsh environmental conditions.

Automotive manufacturers utilize perforated release films in the production of lightweight and strong composite parts for vehicles. These films help achieve optimal resin distribution and consolidation, contributing to improved fuel efficiency, performance, and structural integrity of automotive components.

Perforated release films are also employed in boat building and marine applications to fabricate composite hulls, decks, and structural components. They ensure proper resin flow and air evacuation during the manufacturing process, resulting in durable and corrosion-resistant composite materials suitable for marine environments.

info@gclglobalplastics.com