- Silvassa - 396230, Dadra and Nagar Haveli , India

- info@gclglobalplastics.com

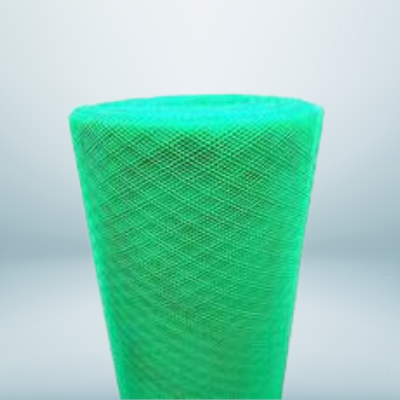

Infusion mesh, also known as flow mesh or flow media, is a specialized material used in resin infusion processes for composite manufacturing. It plays a crucial role in facilitating the uniform distribution of resin throughout the composite laminate, ensuring thorough impregnation of fibers and achieving high-quality composite parts.

Infusion mesh is designed with a grid-like or open structure that promotes the even flow of resin across the entire surface of the composite layup. It helps distribute resin uniformly, ensuring that all fibers are thoroughly wetted and bonded together during the curing process.

Similar to breather fabric, infusion mesh provides pathways for air evacuation during the resin infusion process. As vacuum pressure is applied, the mesh assists in removing trapped air and excess resin from the composite layup, minimizing the risk of voids or air pockets.

Infusion meshes are compatible with various resin systems, including epoxy, polyester, vinyl ester, and others commonly used in composite manufacturing. They are designed to withstand the pressures and temperatures encountered during resin infusion processes without compromising their structural integrity.

info@gclglobalplastics.com