- Silvassa - 396230, Dadra and Nagar Haveli , India

- info@gclglobalplastics.com

Peel Ply, also known as release fabric or release ply, is a specialized fabric used in composite manufacturing processes. It serves a critical role in achieving smooth and clean surface finishes on composite parts, particularly in aerospace, automotive, marine, and wind energy industries.

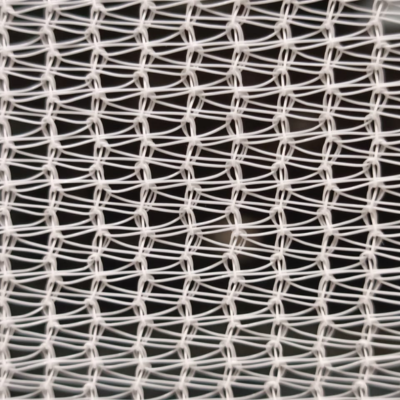

Structure: Knitted fabrics are composed of yarns interlooped in a specific pattern, creating a flexible and stretchable material. The knitted structure allows the fabric to conform easily to complex shapes and contours, making it suitable for applications requiring intricate designs.

Strength and Durability: Depending on the fiber type (such as glass, carbon, aramid, or hybrid blends), knitted fabrics offer varying levels of tensile strength, impact resistance, and durability. These properties make them ideal for reinforcing composite materials to enhance structural integrity.

Conformability: Knitted fabrics exhibit excellent drapability and conformability, enabling them to mold closely to the shape of molds or structures during the layup process. This capability ensures that the fabric adheres tightly to the composite layers, minimizing voids and improving mechanical properties.

Versatility: They are available in a range of weights, widths, and fiber compositions to suit different application requirements. Knitted fabrics can be tailored to meet specific performance criteria, such as strength-to-weight ratio, stiffness, and dimensional stability.

Automotive: Used in automotive manufacturing for reinforcing composite components such as body panels, interior trims, and structural parts. Knitted fabrics contribute to reducing vehicle weight while enhancing strength and crashworthiness.

Aerospace: In aerospace applications, knitted fabrics are employed to produce lightweight yet robust composite structures for aircraft and spacecraft components. They help achieve stringent performance requirements while optimizing fuel efficiency.

Marine: Knitted fabrics play a vital role in boat building for manufacturing composite hulls, decks, and marine structures. They provide excellent resistance to water, corrosion, and environmental factors, making them suitable for marine environments.

Sports Equipment: Used in sports and recreational equipment, such as bicycles, skis, and tennis rackets, to enhance performance through lightweight and durable composite constructions.

Improved Strength-to-Weight Ratio: Knitted fabrics offer superior mechanical properties compared to woven fabrics due to their structure, resulting in stronger and lighter composite parts.

Enhanced Impact Resistance: The inherent flexibility and interlocking yarns of knitted fabrics provide excellent impact resistance, making them suitable for applications requiring resilience and durability.

Reduced Labor Costs: Their conformability and ease of handling during layup processes contribute to reducing labor costs and manufacturing time in composite production.

info@gclglobalplastics.com